HarborChase of the Park Cities: Balustrade System, Exterior Facade using Manufactured Stone

The HarborChase of the Park Cities is an assisted living facility mixed within a high end residential neighborhood and upscale office buildings.

The designers enhanced the brick veneer of this high rise building using elaborate stone cladding. The design is achieved using architectural cast stone. The architect selected stone color and finish that stood out with the red color brick veneer.

The aesthetic appeal of the facility is accentuated by extensive balustrade system built using more than 2,100 balusters.

The wall coping, as well as cornices and banding at different levels of the complex contributed to the unifying design accent.

The stone veneer with full radius arches on the exterior of the first floor resembles continuous limestone facade without any visual discontinuities or externally exposed stone connection details.

Project: HarborChase of the Park Cities

Location: Dallas, TX

Architect: Boka Powell

General Contractor: Beck Construction

Masonry Contractor: DMG Masonry

Completion Date: April 2018

Product: Cast Stone

Awards: CSI Award of Excellence – Manufacturing, UMCA Golden Trowel Award – First Place, Texas Masonry Council (TMC) – First Place

(Scroll down this page to see details of the balustrade system design, or more project images.)

In case of specific questions about your particular project, you are welcome to complete the form at bottom of this page, or on our request support page.

Custom Engineered Balustrade System: Design Assist, Construction Assist

Balustrade system Design with Structural Tubing

Inside Grooves in the Handrail on Top of Balusters Covered Structural Tube Details

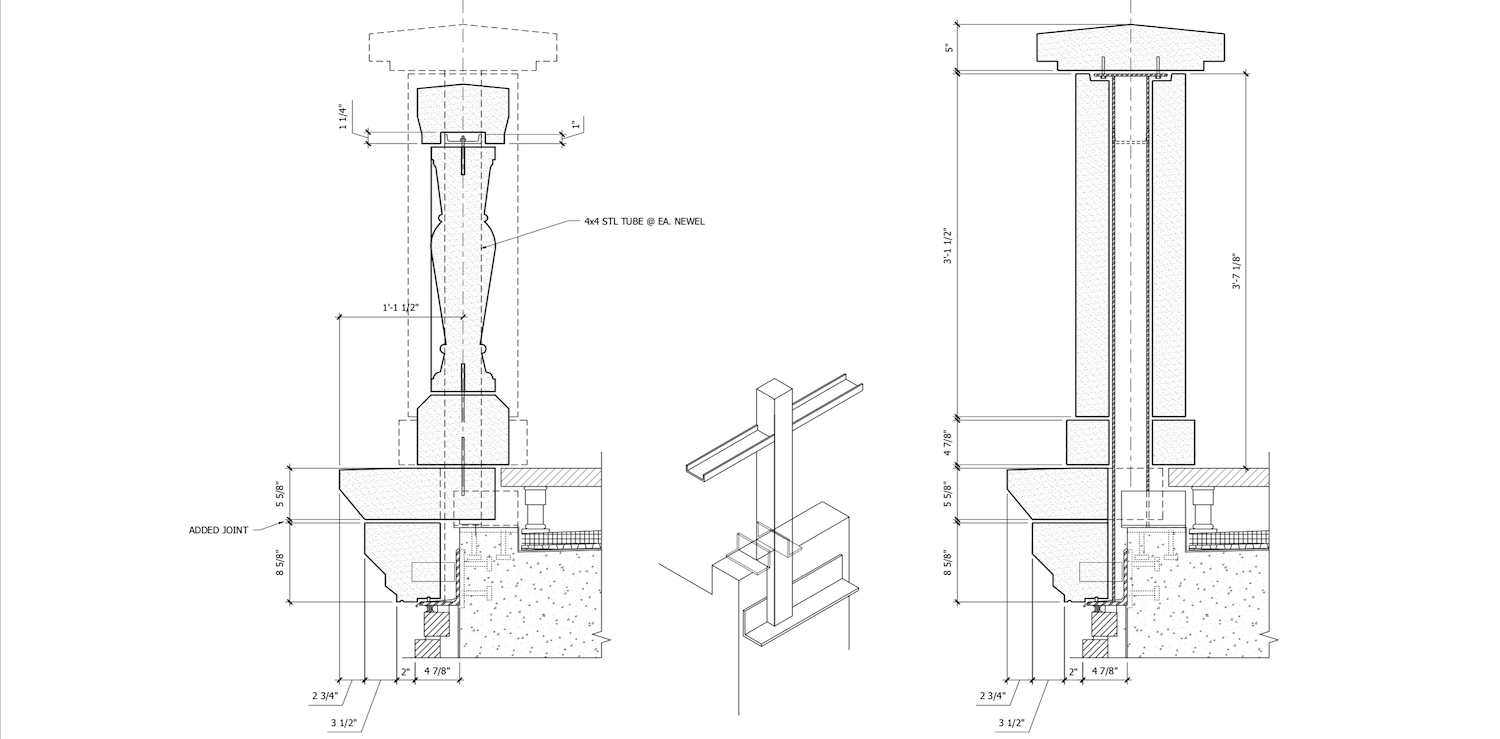

The AAS team custom engineered the balustrade assembly that required structural steel tubing. The design used steel channel that extends through the newel piers and is welded to a vertical, square steel support column. Each baluster is pinned to the steel channel.

The handrail above the balusters is carved out to cover the structural tubing. The tube assembly is hidden by the base and the newel posts throughout.

The AAS team worked with structural engineers for optimum spacing between the steel columns so that the balustrade system has required structural strength.

The design feasibility was confirmed at the start of project using detailed CAD drawings. The AAS team supported the installation team with the fully automated system to track every single stone piece used in the project. Customer got installation guide and also support for onsite troubleshooting during the construction.

Balustrade System Design with Integrated Structural Tubing for Structural Support

Project Specific Stone Manufacturing – Design Support – Project Execution

AAS worked closely with the designers and masonry contractor to confirm design feasibility, installation details.

The custom molds were fabricated using CNC machining. The precise fit of the stone panels without any gaps or connections details enabled manufactured stone veneer that looks like a limestone facade.

Each level of the building is differentiated using stone cornices and banding. The perimeter walls for this complex and hardscape design used matching stone coping adding harmony to the overall design.

This project had over 12,500 total pieces and was constructed on an accelerated masonry schedule of 6 months.

The cast stone balustrade cannot go unnoticed as this building is visible from the heavily traveled North Dallas Tollway.

The consistent color matching across all of stone cladding combined with precise control over size, shape and tolerance requirements for every stone piece helped the architect and contractors for the project realize their vision for a very high end design aesthetic.

If you would like to learn more details about design, manufacturing, construction planning, or installation for this project, you are welcome to complete the form below. If you would like consultation about your specific question, we’d be happy to help you out as well.